Every newsfeed right now is full of “Wait… what?” moments—posts that look normal at first glance, then reveal something completely unexpected. That same dynamic plays out in garages every day. The door still opens, the opener still hums, the concrete still feels solid underfoot—until a small, overlooked flaw becomes an expensive emergency.

Inspired by the current wave of “Wait… what?” posts going viral, this guide takes the same lens to your garage. Instead of laughing at internet oddities, we’ll uncover the subtle, almost invisible issues that quietly compromise safety, security, and long‑term value—and how to resolve them with precision, not panic.

Below are five refined, repair‑focused insights that help you catch problems early, restore performance elegantly, and keep your garage feeling less like a liability and more like a well‑engineered extension of your home.

---

1. The “Looks Fine” Garage Door That’s Quietly Warping

Most homeowners judge their garage door by two things: does it go up, and does it go down. But the real story is written in the gaps along the sides, the way the panels sit in the tracks, and the subtle misalignment that becomes visible when the door is halfway open.

A door that appears normal can, in reality, be carrying uneven loads due to minor warping or sagging. One telltale sign: the door pauses slightly or shudders in a specific spot every time it moves, or daylight shows along one side even when it’s “fully closed.” This isn’t just cosmetic. A warped steel or composite door can strain the opener, accelerate wear on cables and rollers, and compromise security by making it easier to force open. The elegant repair solution is not simply “tightening everything.” A premium approach begins with a balance test—disconnecting the opener and checking if the door stays in place at various heights. If it drops or shoots up, the springs and door weight are out of harmony. A skilled technician will then adjust torsion spring tension, replace fatigued rollers with sealed, high‑quality nylon versions, check track plumb and parallelism, and realign the bottom seal. The goal: a door that moves in a single, fluid line—quiet, balanced, and sealed—rather than one that only appears to be functioning.

---

2. The “Just a Draft” Gap That’s Sabotaging Your Entire Garage

As people share viral posts about malfunctioning cats and “broken” everyday objects, it’s easy to forget that our own homes often behave in similarly puzzling ways. A surprisingly common example: a garage that feels inexplicably cold, humid, or dusty—even after adding insulation or upgrading the door.

The culprit is often a deceptively small gap: a compressed or miscut bottom seal, a worn side weatherstrip, or a misaligned threshold. A mere quarter‑inch opening at the bottom of the door can invite wind‑driven rain, blown dust, pests, and significant heat loss or gain. Over time, this makes climate control in adjacent rooms far less efficient and can encourage rust on tools, corrosion on vehicles, and mildew on stored belongings. The refined fix goes beyond simply swapping the rubber seal. First, the floor is evaluated: is the slab crowned, cracked, or sloping in a way the door can’t fully match? Next, the door’s travel limits and stop position are adjusted so the bottom seal compresses evenly without overloading the opener. If the concrete is irregular, a low‑profile, adhesive threshold—carefully bonded to a cleaned, etched surface—can create a uniform landing strip for the seal. Pair this with high‑quality PVC or rubber side and top seals, and the garage transforms from “perpetually drafty” to properly cocooned, all without visually cluttering the space.

---

3. The “It Still Works” Opener That’s Quietly Unsafe

There is a particular kind of complacency around old garage door openers: if it still responds to the remote, it’s considered fine. Yet, as homeowners share “toxic workplace” and “ignored red flag” stories online, the parallels are hard to miss—small warning signs, dismissed for years, often precede the real crisis.

Openers installed before modern safety standards or poorly maintained over time can become a genuine hazard. Warning signals include: missing or misaligned photo‑eye sensors, no automatic reversal when the door meets resistance, noisy chain drives that jerk and slam to a stop, or openers with fixed‑code remotes easily intercepted by basic scanners. A premium repair strategy treats the opener as a security system, not just a convenience. Start with a force test: gently resisting the closing door should trigger immediate reversal. If it doesn’t, force settings and travel limits must be recalibrated, and the door’s mechanical balance confirmed. Next, assess the safety sensors—height (6 inches off the floor), alignment, and wiring integrity. If the opener is older, lacks rolling‑code encryption, or uses a brittle, exposed chain, replacing it with a modern, belt‑drive unit featuring soft‑start/soft‑stop movement, battery backup, and smartphone integration is not an indulgence; it’s a safety and security upgrade. The difference in noise, control, and reliability is dramatic—and it future‑proofs a critical entry point into your home.

---

4. The “Harmless” Hairline Crack That Signals Structural Stress

Online, people are sharing bizarre things they stumble upon by accident—hidden rooms, strange objects, unexpected finds. In garages, the equivalent is the faint crack in the concrete you notice while pulling in, shrug off, and then rediscover months later… slightly larger.

Not every crack is serious, but many are quietly telling you a story about movement, moisture, or load. A premium repair mindset starts by classifying the crack: is it narrow and stable, or widening and offset? Does water pool along it when it rains? Does it trace from a corner of the foundation, a post base, or the door opening? Superficial shrinkage cracks can often be cleaned and filled with a high‑quality, flexible polyurea or epoxy joint filler to prevent water and road salts from penetrating and undermining the slab. However, a crack that shows vertical displacement (one side higher than the other), repeated widening, or moisture intrusion near walls may indicate deeper settlement or drainage problems. In those cases, the elegant solution is not a quick patch but a professional assessment, potentially involving slab leveling (such as polyurethane foam injection), perimeter drainage improvements, and reinforcement of vulnerable areas. The objective is to preserve a level, structurally sound surface that protects vehicles, storage systems, and the home’s overall integrity—long before “cosmetic” flaws become structural emergencies.

---

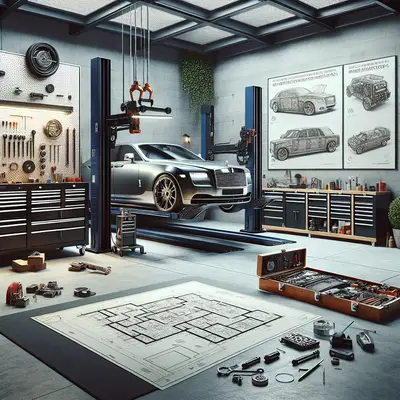

5. The “Organized Enough” Garage That’s Ruining Your Equipment

As social media fascinates over cats in movies and malfunctioning pets, many garages host their own subtle absurdities: precision tools stored under dripping pipes, bikes hung from corroding hooks, or high‑end power equipment perched on the same concrete that floods every heavy rain.

This isn’t simply a matter of aesthetics; it’s about protecting your investment and ensuring that everything you rely on actually works when you need it. A garage that “seems organized” but ignores environmental realities—humidity, temperature swings, minor leaks, dust from vehicles—will quietly destroy bearings, electronics, finishes, and fasteners. The refined repair approach here focuses on infrastructure, not just shelving. First, evaluate where moisture enters: through the door, the slab, or the walls. Addressing door seals and thresholds, as discussed above, is just the start. Consider adding a modest, properly sized dehumidifier with a direct drain line, sealing wall penetrations, and specifying storage that lifts critical items off the floor: powder‑coated steel cabinets, elevated track systems, and ventilated wall panels. For tools and machinery, introduce lined drawers, rust‑inhibiting storage solutions, and dedicated charging stations on surge‑protected circuits—rather than sharing outlets with high‑draw appliances. These aren’t decorative upgrades; they are targeted repairs to a flawed environment, aligning your garage with the way high‑performance workshops protect their assets.

---

Conclusion

Our online lives are saturated with “Wait… what?” moments, but the most consequential surprises are often hiding much closer to home—behind a seemingly ordinary garage door, beneath a faint crack, or inside a system that “still works” but no longer works well.

By treating your garage less like a forgotten storage bin and more like a finely tuned entry pavilion, you shift from reactive fixes to deliberate, sophisticated repair solutions. You balance the door instead of just forcing it. You seal the slab intelligently instead of merely caulking. You upgrade safety, security, and protection with the same discernment you’d apply to any other high‑value asset.

The result is not only fewer emergencies, but a quieter, safer, and more elegant everyday experience—where the only “Wait… what?” moments are the ones you scroll past online, not the ones you discover in your own garage.

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Repair Solutions.