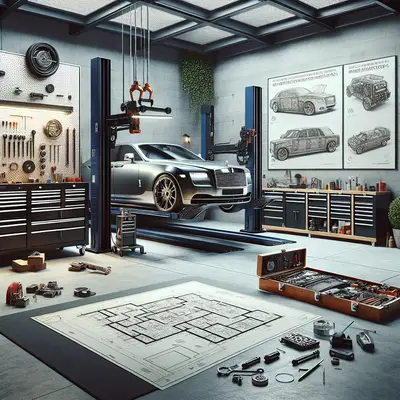

The most refined homes treat the garage not as an afterthought, but as a performance space—where mechanisms must respond instantly, quietly, and without complaint. When something fails, the objective is not a quick patch; it is a repair that restores confidence, preserves property value, and anticipates the next decade of use. This guide explores elevated repair solutions that go beyond obvious fixes, revealing subtle interventions and diagnostic habits that discerning homeowners quietly rely on.

Seeing the Garage as a Mechanical Ecosystem

Most repair frustrations begin with a narrow view: treating the garage door, opener, floor, and structure as isolated components. A premium repair strategy treats the garage as an integrated mechanical ecosystem, where minor irregularities in one area echo elsewhere.

Instead of asking, “What’s broken?” the better question is, “What changed, and how does it affect the system?” A sluggish door may be less about the opener’s motor and more about spring fatigue, misalignment, or binding tracks. Vibration in the door can originate from imbalanced torsion springs, poorly anchored hardware, or even subtle foundation movement affecting track plumb and level.

An elevated approach starts with a systematic survey: door operation, noise profile, travel smoothness, seal contact, structural anchoring, and how the door behaves in manual mode with the opener disconnected. From there, repairs are chosen not simply to restore function, but to refine balance, reduce stress on components, and extend service intervals. The result is a repair strategy that feels less like crisis management and more like mechanical curation.

Exclusive Insight #1: Treat Noise as a Diagnostic Instrument, Not an Annoyance

In a demanding home, excessive garage noise is simply unacceptable—but it is also information. Different sounds point to different failure patterns, and listening precisely can reveal where a professional’s attention should go before components fail outright.

A rhythmic clunk or “thud” during travel often signals flat spots or misalignment in rollers, or a loose hinge causing the door sections to shift under load. A metallic scraping suggests misaligned tracks or a bent track flange, frequently caused by minor impact that went unnoticed. High-pitched squealing during operation tends to indicate dry bearings or bushings in rollers or the opener’s drive mechanism, especially in older chain-drive systems.

The refined repair response is not to flood everything with lubricant. Instead, it begins with tightening, aligning, and balancing before the first drop of lubricant is applied. Once hardware is correctly fastened and tracks are trued, a targeted application of high-quality, garage-door-specific lubricant to hinges, rollers (if non-sealed), and springs dramatically reduces sound. The outcome is not just quiet operation; it is reduced friction, lower motor strain, and fewer premature component failures.

Exclusive Insight #2: Balance Before Power – The Hidden Foundation of Reliable Operation

When garage doors struggle, many homeowners instinctively blame the opener. In practice, the opener is the last link in the chain. A truly premium repair sequence addresses door balance and counterweight before even considering an opener replacement.

A well-balanced door, when disconnected from the opener, should remain near where it is placed along its travel, rather than slamming down or shooting up. If it drifts strongly in either direction, the torsion or extension springs are no longer correctly calibrated for the door’s weight. This imbalance forces the opener to act as both lifter and brake—dramatically accelerating wear on gears, drive belts, and electrical components.

A sophisticated repair solution involves professional spring calibration or replacement, matched to both the weight and construction of the door (insulated, glass inserts, steel gauge, wood cladding, etc.). Only after restoring mechanical balance does it make sense to evaluate the opener’s condition. Homeowners who insist on balance-first repairs routinely see their openers last years longer than those who simply upgrade motor units without addressing the underlying mechanical load.

Exclusive Insight #3: Weather Seals as Silent Guardians of Structure and Equipment

For many, bottom and perimeter seals are a cosmetic afterthought; for a demanding homeowner, they are a structural safeguard. Properly selected and installed seals protect finished flooring, stored vehicles, tools, and mechanical systems from the daily assault of water, wind-driven debris, and temperature swings.

In climates with freeze-thaw cycles, deteriorated bottom seals allow water to creep under the door and collect near the slab edge. Even modest seasonal moisture can contribute to hairline cracking, surface spalling, or subtle heaving near the threshold—issues that later complicate track alignment and door seating. In coastal or high-humidity environments, poor sealing introduces corrosive air and moisture that quietly oxidize springs, cables, and metal hardware long before their expected lifespan.

A refined repair strategy specifies seals based not on the cheapest available option, but on door material, exposure, and climate. Heavier-duty vinyl or rubber bottom seals with robust aluminum retainers, bulb designs that accommodate slight slab imperfections, and high-quality side and top seals matched to the door’s finish help maintain a controlled microclimate inside the garage. The visual result is clean, sharp door lines; the practical result is reduced corrosion, fewer electrical issues from humidity, and more stable temperatures that also support any adjacent conditioned spaces.

Exclusive Insight #4: Structural Anchoring and Hardware as the Quiet Insurance Policy

Many repair visits focus on the moving parts: springs, belts, rollers, and motors. However, the longevity and safety of a garage system often depend on items that rarely draw attention—lag bolts, brackets, jamb fasteners, header attachments, and track anchors.

Over time, vibration, door impacts, seasonal expansion and contraction, and even minor settling can loosen or slightly shift structural fasteners. Once anchoring begins to relax, tracks can move a few millimeters out of alignment, bearing plates may rotate, and opener mounting can begin to flex. These small deviations can manifest as rubbing, binding, or inconsistent door travel that is often misattributed only to the opener or springs.

An elevated repair protocol includes a structured hardware audit: checking torque on lag screws, verifying that fasteners are embedded into solid framing and not just sheathing, confirming that bearing plates are perfectly square to the shaft, and ensuring tracks are plumb, parallel, and correctly spaced. Where the framing is marginal, the solution may include backing plates, upgraded fasteners, or even select carpentry to provide a proper anchoring substrate.

The effect is subtle but profound: quieter operation, fewer emergency service calls, and dramatically reduced risk of catastrophic hardware failure—particularly important for heavier, custom, or fully insulated doors.

Exclusive Insight #5: Intelligent Upgrades That Preserve Aesthetic and Reduce Future Repairs

High-end garages often serve multiple roles: vehicle storage, workshop, gym, or even a secondary entry into the home’s living space. Repair decisions that only consider “fixing today’s problem” often lead to mismatched components, awkward controls, or visually intrusive add-ons. A premium strategy treats every repair as an opportunity to quietly modernize the system without disrupting the architecture.

Instead of defaulting to the most powerful or most advertised opener, homeowners can prioritize drive type (belt vs. chain vs. direct drive), integrated motion-sensor lighting, battery backup for power outages, and secure smart controls that align with the home’s existing ecosystem. Soft-start and soft-stop technology, for example, not only feels luxurious but also reduces stress on the door’s structure, hinges, and hardware, lowering future repair frequency.

Similarly, when addressing recurring problems—such as roller failures or frequent cable fraying—a refined solution might specify upgraded nylon rollers with sealed bearings, high-tensile-strength cables, or corrosion-resistant hardware suited to local environmental conditions. Each improvement maintains visual discretion while substantially elevating long-term reliability. The homeowner experiences fewer disruptions, cleaner sightlines, and a garage that feels quietly current rather than patched together over time.

Conclusion

Excellence in garage repair is rarely about a single dramatic intervention. It is the accumulated effect of balanced springs, silent hardware, precisely tuned tracks, intelligent sealing, and thoughtfully selected openers and components. Homeowners who demand more than basic functionality understand that each repair is a chance to refine the entire mechanical environment of the garage, not just correct an obvious failure.

By treating noise as data, balance as non-negotiable, seals as structural protection, anchoring as insurance, and upgrades as an opportunity for subtle modernization, you transform repairs from reactive chores into strategic enhancements. The result is a garage that behaves with the same composure and precision you expect from the rest of your home—responsive when needed, invisible when not.

Sources

- [U.S. Consumer Product Safety Commission – Garage Door Safety](https://www.cpsc.gov/s3fs-public/garage.pdf) – Federal guidance on garage door safety features and best practices for safe operation

- [International Association of Certified Home Inspectors (InterNACHI) – Garage Inspection Guidelines](https://www.nachi.org/garage-inspection.htm) – Professional standards and common failure points in residential garage systems

- [Clopay Garage Doors – Care & Maintenance Recommendations](https://www.clopaydoor.com/garage-door-care) – Manufacturer guidance on proper maintenance, balancing, and sealing of garage doors

- [LiftMaster – Garage Door Opener Support & Features](https://www.liftmaster.com/customer-support) – Technical information on modern opener technology, noise reduction, and safety features

- [University of Minnesota Extension – Managing Moisture and Home Foundations](https://extension.umn.edu/problem-prevention-and-maintenance/managing-moisture-around-your-home) – Insight into how water and moisture around the garage can affect slabs, framing, and long-term structural performance

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Repair Solutions.