Across discerning homes, the garage is often the largest moving system and one of the most technically complex components on the property—yet it receives the least deliberate care. When maintenance is reduced to “does it open and close?”, small flaws accumulate quietly: a strained opener here, a misaligned track there, a slow moisture leak in one corner. Left alone, they begin to erode comfort, security, and even property value.

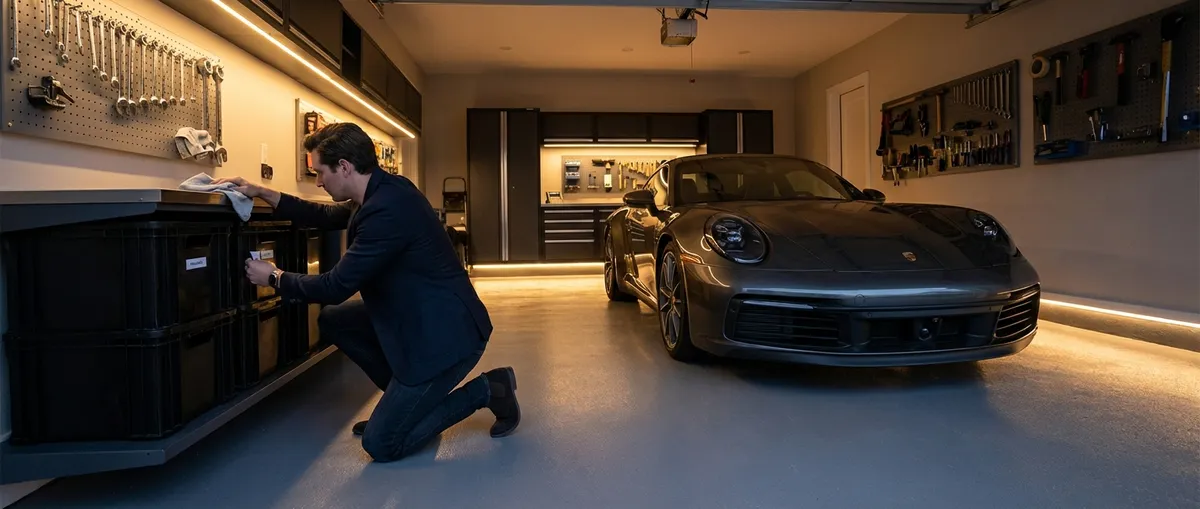

This is where a more refined approach to maintenance earns its place. Not the quick spray of lubricant on a noisy hinge, but a thoughtful, scheduled, and measured discipline that treats the garage as an integrated system—mechanical, structural, and environmental. What follows is an elevated look at maintenance decisions that extend well beyond the obvious, with five exclusive insights for homeowners who expect their garage to perform as well as the rest of their home.

The Garage as a System, Not a Door

A garage that truly performs is never just “a door that works.” It is a synchronized system of load-bearing hardware, calibrated electronics, structural elements, and environmental controls. When you begin maintenance with this systems mindset, you stop chasing symptoms (the squeak, the hesitation, the draft) and start managing causes.

Viewing the garage as a system means acknowledging how much is quietly interdependent. Track alignment affects opener strain; torsion spring balance affects motor life; floor drainage influences rust formation on the lower door sections and hardware. Even lighting and power layout have a maintenance dimension—poor illumination encourages neglect, and overloaded circuits shorten the life of openers and auxiliary equipment.

Schedule a holistic review once or twice a year. Not just the door, but the opener, hinges, rollers, seals, wall framing near the tracks, floor condition, and even the ceiling structure that carries the opener and spring assemblies. Document what you see—photos, short notes, timestamps. That record, however simple, transforms future repairs from reactive guesswork into informed, strategic decisions.

Precision Tuning vs. Quick Fixes

Most garages are “kept going” with improvised fixes: a heavier lubricant to mask noise, an extra twist on an already overworked spring, a slightly bent track “corrected” by hand. These solutions feel economical, but they quietly trade away lifespan and reliability.

Precision tuning takes the opposite approach. Instead of forcing the system to behave, it restores the conditions under which the hardware was designed to operate. That means centering the door properly in its opening, ensuring tracks are plumb and parallel, confirming that all fasteners are tightened to appropriate torque, and verifying that the door is genuinely balanced before the opener ever engages.

A refined tuning session will include a meticulous check of roller performance, hinge play, and the door’s travel against the weatherstripping. Any component that has excessive slop or visible deformation should be replaced, not “nursed.” The door should glide smoothly by hand, with the opener disconnected, and remain in place when positioned halfway. If it insists on rising or falling on its own, the springs are not correctly balanced—forcing the opener to act as a lifting device instead of the guiding assistant it was engineered to be.

When you invest in precision instead of patches, the benefits compound: quieter operation, dramatically less strain on motors and springs, fewer emergency calls, and a garage that feels intentionally maintained, not tolerated.

Five Exclusive Maintenance Insights for Demanding Garages

Homeowners with exacting standards tend to want more than basic checklists. The following five insights focus on details that rarely appear in typical advice but deliver outsized benefits in longevity, comfort, and safety.

1. Treat the Bottom Seal as a Structural Component, Not a Consumable

Most people view the bottom rubber seal as an afterthought—something to be replaced only when daylight appears. In reality, it is a first-line defense against moisture, insect intrusion, and micro-movements that fatigue the lower door section.

When the seal hardens, flattens, or tears, the door no longer spreads its weight uniformly on the floor. Small gaps concentrate load on corners or the panel edge, accelerating warping and allowing minor water intrusion that can wick into the door skin or hardware. On steel and composite doors, this can translate into rust around the bottom fixtures; on wood, it encourages swelling and eventual delamination.

Adopt the same standards you would for weather seals on high-end entry doors: inspect seasonally, clean the contact points, and replace aggressively at the first signs of stiffness, cracking, or uneven compression. When feasible, upgrade to a higher-grade seal material designed for your climate—cold-weather elastomers for harsh winters, UV-resistant formulations for intense sun exposure.

2. Balance Spring Maintenance with Opener Protection

Springs are often treated as a single, risky event—ignored until they break. Yet they are the backbone of your entire lifting system, and their condition has a direct, measurable impact on opener health.

An under-tensioned or worn spring forces the opener to drag a door that is effectively heavier than its designed load. The result is overheated motors, stressed gears, and shorter service life. Conversely, springs that are over-tensioned can slam the door open or closed, stressing hinges, tracks, and the opener’s drive system.

Instead of waiting for failure, insist on preventative spring maintenance with recalculation and, when appropriate, redesign. For heavier, fully insulated, or custom-clad doors, have a qualified professional confirm that spring sizing actually matches the door’s present weight, not what it weighed before a previous upgrade. In some cases, converting from a single torsion spring to a dual-spring configuration can distribute stress more evenly, providing a more controlled motion and graceful failure behavior if one spring ever does break.

3. Assign a “Moisture Map” to Your Garage Floor

Water is the silent saboteur of garage performance. It rusts lower tracks, corrodes base plates, invites mold to drywall edges, and spalls concrete. Yet most homeowners never formally track where water actually travels and lingers.

After the next heavy rain, snowmelt, or car wash, step into the garage with the intention of creating a mental “moisture map.” Note exactly where water pools, where it creeps toward the walls, and how long it takes to evaporate. Revisit this observation in different seasons.

This simple practice guides smart maintenance priorities: perhaps a subtle floor re-leveling is warranted near the garage entry, a shallow trench or channel drain will prevent water from advancing to interior walls, or a small curb at the base of a back wall could protect framing from chronic dampness. Once you see the patterns, you can break them—with solutions far less invasive than a full floor replacement.

4. Audit the Attachment Points, Not Just the Visible Hardware

The best-maintained garage doors sometimes fail at the point everyone forgets: the structure they are anchored to. Lag screws may be tight in brackets, yet loose or compromised in the wood or masonry behind them. Over time, repeated motion can elongate holes, compress fibers, or fracture masonry anchors.

Include a structural attachment audit as part of your annual maintenance ritual. Focus on:

- Header and jamb framing where tracks and springs mount

- Ceiling joists or trusses carrying the opener and torsion shaft

- Any wall anchors holding safety containment or reinforcement kits

Look for hairline cracks in surrounding material, crushed wood fibers, or fasteners that withdraw easily under slight load. Reinforcement—such as backing boards, upgraded anchors appropriate for your wall material, or properly sized blocking—transforms the system from “adequate for now” to confidently overbuilt. This is especially critical for heavier custom doors or homes in seismic or high-wind regions.

5. Synchronize Safety Sensors with Real-World Clutter

Photo-eye sensors are usually installed to meet code, not to align with the way you actually live in and use the garage. Over time, bicycles, seasonal storage, yard tools, or even decorative elements migrate into the beam’s path, causing nuisance reversals and desensitizing everyone in the home to what the safety system is telling them.

Instead of accepting random inconvenience, deliberately choreograph sensor placement to suit your traffic. Mount them at the appropriate height per manufacturer specifications, but adjust lateral positioning and angle with intention: clear of storage zones, away from shelving edges, and not in the natural path of swinging car doors or stroller wheels. Confirm they are firmly mounted to resist accidental bumps.

Then, treat sensor testing as non-negotiable, similar to checking smoke alarms. Once a month, use a solid object (never a person or pet) to interrupt the beam during closing and confirm immediate reversal. This habit validates that the system is not just present, but performing—quiet insurance against the moment you need it most.

Environmental Control: The Overlooked Maintenance Lever

Temperature, humidity, and air quality dictate how gracefully your garage ages. An unconditioned, unventilated garage cycles through extremes that punish materials: wood swells and contracts, metal sweats and corrodes, finishes yellow, and electronics fatigue prematurely.

Maintenance, in this context, becomes a set of environmental corrections rather than just mechanical adjustments. Inspect and maintain weatherstripping not only for drafts but for its role in dampening temperature swings. Consider modest upgrades: a well-calibrated exhaust fan, a humidity-controlled vent, or even a low-profile mini-split in garages that store sensitive equipment, high-end bicycles, or classic vehicles.

Monitor humidity with a dedicated hygrometer and look for readings that consistently exceed comfort levels, especially in shoulder seasons. Persistent high humidity calls for targeted intervention—sealing floor cracks that wick moisture, adding a dehumidifier with a proper drain path, or improving insulation transitions between the house and the garage. Each of these measures indirectly lightens the maintenance burden on everything from door panels to stored belongings.

When to Call for Expert Intervention

A premium maintenance philosophy includes knowing where the line is—what should be handled in-house and what should be entrusted to professionals with the tooling and training to work safely and precisely.

Anything involving torsion springs, significant track realignment, opener motor replacement, or structural reinforcement near load-bearing elements belongs in the professional category. The objective is not to surrender control but to curate which tasks will be done with expert-level precision.

When selecting a service provider, look for evidence of process, not just availability: documented inspection checklists, clear explanations of load calculations and part selection, and a willingness to discuss long-term implications, not just immediate fixes. The right partner will not simply “repair the problem” but help you refine a maintenance roadmap, identifying which interventions today will prevent tomorrow’s disruptive failures.

Conclusion

A garage that operates with quiet confidence is never an accident. It is the result of a deliberate maintenance philosophy that values alignment over improvisation, balance over brute force, and foresight over emergency calls. By re-framing your garage as a system, treating humble components like seals and fasteners as critical actors, mapping moisture, and curating professional interventions where they matter most, you protect not only a convenience but a substantial, often underappreciated slice of your home’s value.

For those who expect their homes to age gracefully rather than merely endure, the garage deserves nothing less than meticulous, thoughtful care—executed with the same standards you would demand from any other precision system in your life.

Sources

- [U.S. Consumer Product Safety Commission – Garage Door Safety](https://www.cpsc.gov/garage-door-openers) – Overview of safety standards and key risk factors related to garage door systems

- [International Association of Certified Home Inspectors – Garage Inspection Guidelines](https://www.nachi.org/garage-inspection.htm) – Detailed guidance on structural, mechanical, and safety considerations for residential garages

- [U.S. Department of Energy – Air Sealing Your Home](https://www.energy.gov/energysaver/air-sealing-your-home) – Explains the importance of weatherstripping, seals, and moisture control around openings like garage doors

- [Portland Cement Association – Concrete Floors and Moisture](https://www.cement.org/learn/concrete-technology/concrete-construction/concrete-floors-and-moisture) – In-depth discussion of how moisture affects concrete slabs and best practices for mitigation

- [University of Minnesota Extension – Managing Home Humidity](https://extension.umn.edu/mold-and-indoor-air-quality/managing-humidity-your-home) – Practical guidance on indoor humidity control and its impact on building materials and systems

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.