The most refined homes are often defined not by what guests see, but by what they never notice—doors that glide without protest, mechanisms that perform without complaint, and spaces that work as beautifully as they look. Your garage is one of the most mechanically complex elements of your property, yet it is frequently the least curated. Thoughtful, premium repair solutions can transform it from a point of frustration into a silent, disciplined extension of your home’s standards.

What follows are five exclusive, detail‑driven insights for homeowners who expect more than “good enough” from every moving part of their residence.

1. Treat the Garage Door as an Engineered System, Not a Collection of Parts

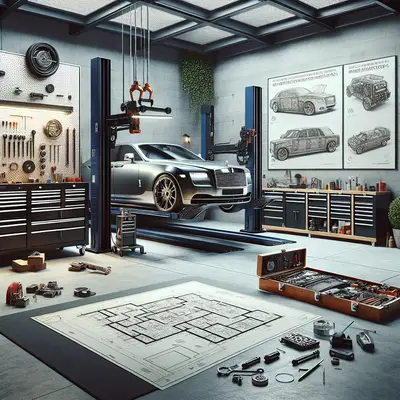

Most repairs fail prematurely because the door is treated piecemeal: a squeak here, a broken spring there, a misaligned sensor in the corner. A premium approach begins with recognizing the door as a balanced, engineered system in which every component influences the others.

A comprehensive repair assessment should begin with the fundamentals: verifying door weight against spring rating, checking track plumb and level, inspecting panel integrity, and confirming opener capacity relative to the door’s mass and usage. A door that is correctly balanced will stay suspended at mid‑travel with minimal force; if it slams shut or shoots open, the springs are doing the wrong work—or too much of it. Replacing a worn opener without correcting the balance simply transfers strain and shortens the life of new equipment.

The most effective technicians will also test for subtle torsional twist in the shaft, micro‑bending in the tracks, and looseness in fasteners that anchor into framing members. Proper system‑level repair results in a door that moves with a single, fluid motion and an opener that no longer has to “fight” the hardware to do its job.

2. Prioritize Structural Integrity Before Cosmetic or Mechanical Fixes

Refined homeowners often focus first on appearance—fresh paint, new trim, or upgraded hardware. Yet a premium repair strategy begins with what is embedded: the structure that supports every movement you ask of the door and equipment.

A meticulous evaluation will examine the header above the opening for sagging, splitting, or moisture damage; the jambs for racking or twist; and the anchor points where tracks and hinges meet framing. Even a slight structural deflection can force rollers to bind, cause doors to rub, and place chronic stress on springs and openers. Repairing only the mechanical symptom, without correcting the structural cause, risks recurring failure.

In some cases, the most elegant solution is invisible: steel reinforcement strapping behind interior drywall, upgraded fasteners into solid framing, and corrosion‑resistant brackets that tie the system together. Only once this quiet backbone is secure should you move on to panel replacement, hardware finishes, or upgrades in automation. Precision at the structural level ensures every subsequent repair performs to its full potential.

3. Specify Components to Your Lifestyle, Not Just to the Door

Two identical garage doors can require very different repair strategies depending on how they are used. A door that opens six times a day for a small household has radically different demands than one cycling constantly for a multi‑car family, home gym, or workshop. The highest tier of repair solution considers your usage pattern as carefully as the door’s dimensions.

When replacing springs, for instance, you can select higher‑cycle torsion springs designed to withstand significantly more openings and closings before fatigue. Similarly, openers are not all created equal: a belt‑drive unit with soft‑start/soft‑stop can be matched with a DC motor for quieter, smoother operation, while a wall‑mounted jackshaft opener may be ideal for high‑ceiling garages or those with unique overhead storage or lift systems.

Even the choice of rollers and hinges can be curated: sealed bearing nylon rollers, heavy‑gauge steel hinges, and weather‑resistant bottom seals tailored to your climate yield a door that feels “over‑engineered” in the best possible way. Instead of defaulting to standard builder‑grade components, specify parts based on usage, environment, and your tolerance for noise, vibration, and maintenance. This turns a routine repair into a long‑term enhancement of daily experience.

4. Design Repairs with Environmental and Moisture Realities in Mind

A garage is a transitional space—exposed to the outdoors yet closely linked to conditioned interiors. Repairs that ignore temperature swings, humidity, and local weather patterns quickly show their limitations. A sophisticated repair strategy integrates building‑science thinking into every decision.

In coastal or high‑humidity regions, for example, corrosion resistance should be non‑negotiable for springs, fasteners, and hardware. Galvanized or powder‑coated components, stainless hardware in critical locations, and properly sealed weatherstripping at the perimeter all extend the life of the repair. In colder climates, premium bottom seals, threshold seals, and side weatherstripping help reduce drafts and incidental moisture ingress—interrupting the freeze‑thaw cycles that can buckle concrete at the door line and damage stored belongings.

Even small decisions, like specifying low‑VOC sealants and paints or choosing insulated replacement panels during a repair, can meaningfully improve comfort and indoor air quality. Layered together, these choices shift the garage from “buffer zone” to a controlled, well‑behaved part of the home, where repairs are not just fixes but thoughtful environmental upgrades.

5. Elevate Safety and Diagnostics to the Same Level as Aesthetics

In discerning homes, elegance is never at odds with safety—it includes it. Yet garage repairs often prioritize visual restoration and basic function while leaving safety and diagnostic capacity as afterthoughts. The most exceptional repair solutions embed protection and insight directly into the system.

A comprehensive safety‑focused repair will start with redundant checks: testing and recalibrating auto‑reverse mechanisms, verifying photo‑eye alignment with a digital level, and confirming that manual release mechanisms operate smoothly and intuitively. In households with children, pets, or frequent deliveries, these checks are not optional; they are part of a premium standard of care.

The next tier involves diagnostics. Modern openers with integrated smart technology can notify you of abnormal operation patterns, unexpected openings, or doors left ajar. When combined with high‑quality repairs, this data gives you early warning of emerging issues—before they become failures. You move from reactive crisis management to proactive stewardship: scheduling targeted service based on real usage and performance rather than guesswork or neglect.

In this way, safety systems and smart diagnostics stop being utilitarian add‑ons and become part of the garage’s refined, intelligent character—quietly watching over a complex mechanism so you don’t have to.

Conclusion

A garage should not be the mechanical outlier in an otherwise carefully curated residence. When you treat repairs as an opportunity to refine engineering, structure, component selection, environmental performance, and safety, the space begins to align with the rest of your home’s standards.

The difference is subtle yet unmistakable: a door that moves with composure, hardware that feels reassuringly solid, and systems that anticipate problems rather than creating them. Exceptional garage repair is not about visible drama; it is about restoring a sense of calm, precise reliability to one of the hardest‑working thresholds in your home—quietly elevating the everyday.

Sources

- [U.S. Consumer Product Safety Commission – Garage Door Safety](https://www.cpsc.gov/s3fs-public/garage.pdf) - Official guidance on safe operation and maintenance of automatic garage doors

- [International Association of Certified Home Inspectors – Garage Door Inspections](https://www.nachi.org/garage-door-inspections.htm) - Technical overview of door components, safety features, and common defects

- [U.S. Department of Energy – Insulated Garage Doors](https://www.energy.gov/energysaver/insulated-garage-doors) - Explains energy and comfort benefits of upgraded door assemblies and seals

- [Clopay Garage Doors – Torsion vs. Extension Springs Explained](https://www.clopaydoor.com/faq/garage-door-springs-torsion-vs-extension) - Manufacturer guidance on spring types, cycles, and performance considerations

- [Overhead Door Company – Garage Door Opener Safety & Features](https://www.overheaddoor.com/blog/garage-door-opener-safety-features) - Details modern safety technologies and functional enhancements for openers

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Repair Solutions.